About Our Company

TATPL as a Turnkey Solution Provider for Pharmaceuticals, Hospitals, R&D Centers, Food processing units & Microelectronic industry.

-

TATPL was established in 2007 as a manufacturing unit with the aim to provide Turnkey solutions with customized manufacturing Quality products and on-time delivery

-

TATPL has committed all clients for economic world-class quality products supplied with continuous R&D in all of our product range

-

During the years TATPL served many clients in the domestic and international markets with countries like Russia, Ukraine, Georgia, Cameroon, Vietnam, Egypt, etc.

-

TATPL has the right balance in our team of young & enthusiastic professionals with experienced & senior professionals which enables us to cope of serve various emans from the market for quick ans easy solutions.

-

TATPL has a total strength of 70 people which makes us take turnkey projects for various cleanroom standards like USFDA, MCA, MHRA, WHO, FDA, etc.

15 years+ Experience

Our Key Members

Apurva Chavda(Technical Director / Marketing)

+91-9879003546Rohit Kela(Designing / Drawing)

+91-8980866600G S Chavda(Finance / HR)

+91-9714884900Sujal

+91-9714882100Kuldeep

+91-9979010861Jinesh

+91-9714881200Soniya

+91-9714882900Vinit(Domestic Marketing)

+91-8238980522Bhavesh(Laminars)

+91-9712171986Bhargav(Site Executive)

+91-9714887200Alkesh(Production)

+91-9714999366Jitendra(Site Engineer)

+91-9898263866Yash(Stores)

+91-9726416012Dhruvpal(Dispatch)

+91-8780954581Nirmal(Purchase)

+91-9824351557Our Production facility

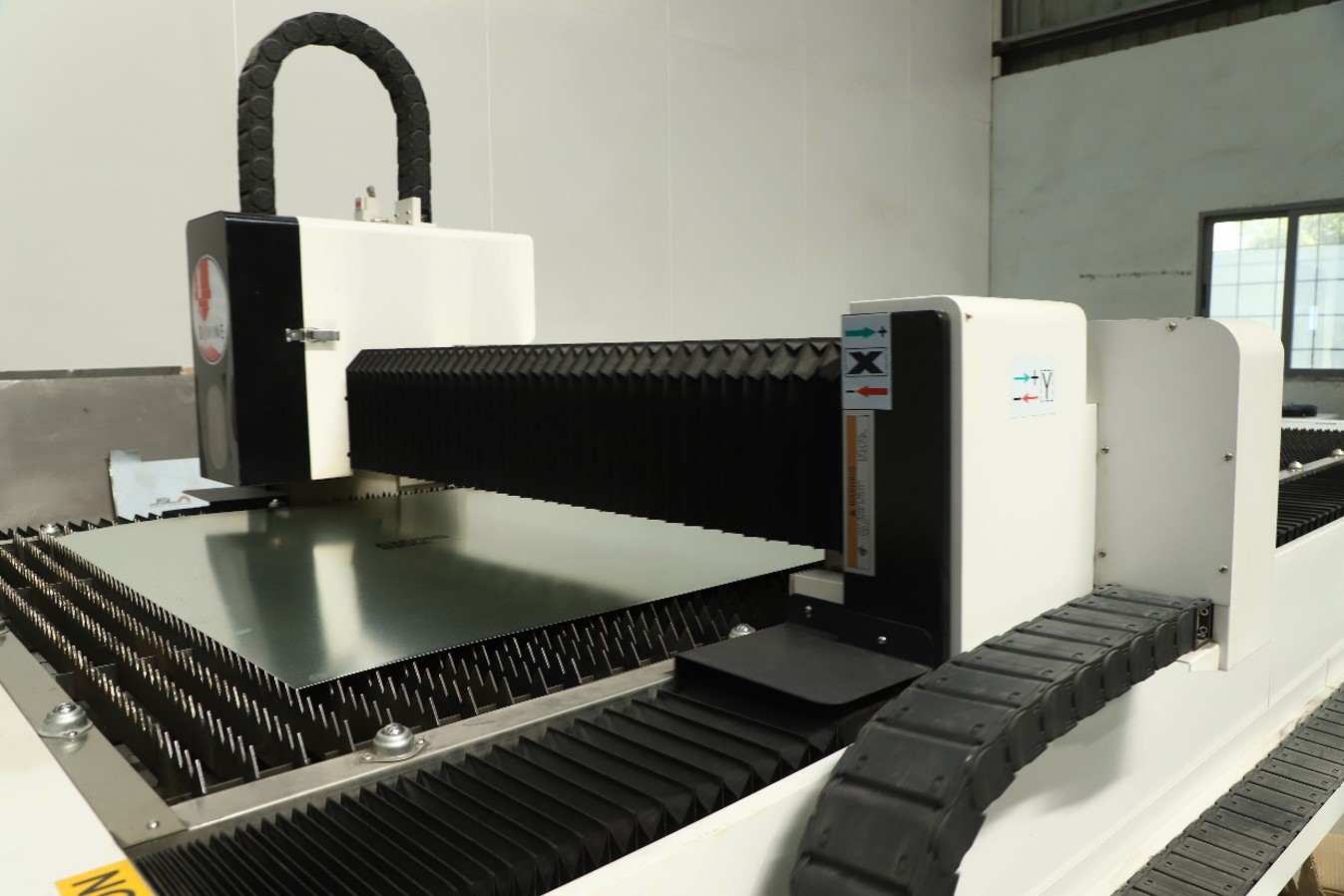

TATPL has state of an art manufacturing facility in a 50,000 sq. ft. area with 30,000 sq. ft. as factory premises The following set of equipment is in house to achieve the best quality products for timely deliveries:

- Roll-Forming machine for GI Profiles - 1No.

- Coil Cutting Machine –1No.

- Laser Cutting Machine (5x1.5mtr) –1No.

- CNC bending (4M) –1No.

- CNC bending (3M) –1No.

- NC Bending (3M) –1No.

- Shearing Machine (4M) –1No.

- Shearing Machine (3M) –1No.

- Robotic Powder Coating Plant –1No.

- Manual Powder Coating plant –1No.

- PU Filling machine with bed press –1No.

- Validation Kit with Thermal Anemometer, PAO Test, Particle Count Test & Flow Pattern Test